Being a natural product that is kiln fired, there will always be some tiles in each batch that show imperfections on the surface.

Before packaging, tiles are sorted and any with visible imperfections are removed and graded and sold as seconds. A small number will always slip through the system. These tiles are perfectly sound, but imperfect all the same.

The international standard allows 5% of any first grade consignment to have some visual imperfections. There are a few factories that will allow up to 15%. 5% means that up to 5 tiles may havbe some imperfections in each group of 100 tiles. The tiler will always put these tiles aside and use them when a cut tile is needed.

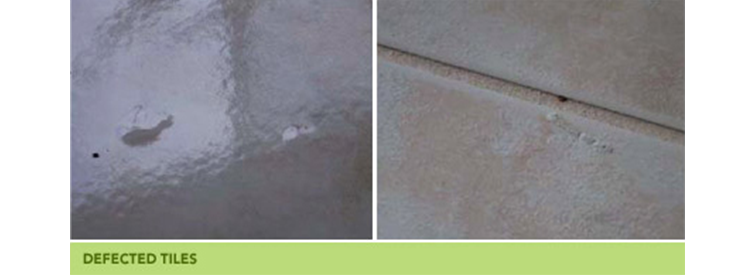

If you have a tiling project that has obvious imperfect tiles installed, then it is simply because the tiler has not checked the tiles as he laid them. Defects such as firing cracks, craters, bubbles, pinholes, smudged patter, etc. are all visible flaws and the installer should put these tiles aside for when cut tiles are needed.

If a few imperfect tiles have been laid, there are two options open to you. Either accept that there are a few imperfect tiles in the installation, or replace them.

If you have a few spare tiles left on the job, the tiler will be able to replace the suspect tiles.

If you don't have spare tiles you will need to find out what the batch or shade of the tiles is. Visit your Ranjanas Ceramic Branch and the staff will be able to determine if that shade is still available.